At the Sarnia refinery, we know community members are concerned about flaring. Why do we flare? Is it safe? We asked our Community Relations student to find out about flaring and explain it from the perspective of someone who is not experienced with the process. Here’s what they learned.

Flaring occurs when pressure from the refinery’s operations builds up and needs to be released. Most of the time, pressure inside the refinery is controlled and there is no need to flare. It sometimes becomes necessary when the refinery experiences unexpectedly high pressure, which can be due to weather-related events, maintenance, or operational changes.

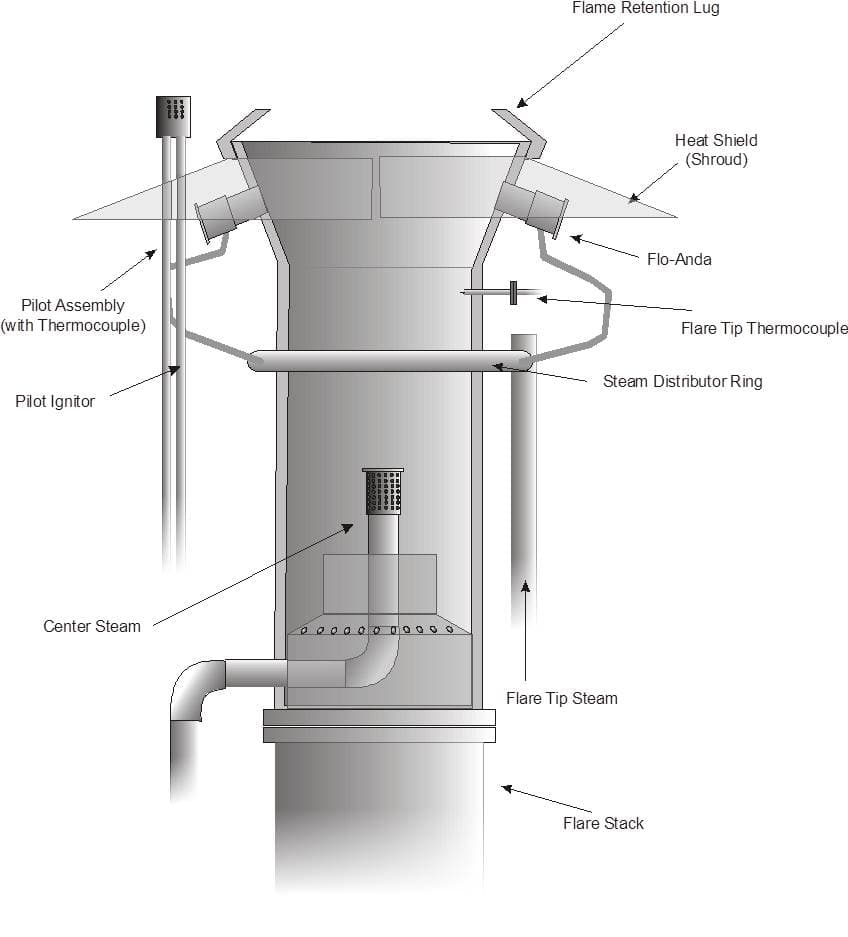

Flaring is a vital safety feature that relieves pressure by combusting flammable gases and dispersing them high into the air rather than at ground level. There are relief valves throughout the refinery that open and vent into the flare system if the pressure becomes too high.

The highlight of the flare system is the Flare Gas Recovery Unit, affectionately referred to on-site as the FGRU. The FGRU will remove any liquid in the material being sent to the flare, including liquid natural gas, which helps reduce the size of the flare. Anything that can be saved is recovered, cleaned and re-used as fuel for heaters in the refinery.

Since 2012, we have been able to make significant improvements in reducing flaring at the Sarnia refinery. These improvements have been made possible by many hardworking team members who ensure safety is always placed above all else. They are focused on checking for issues before they arise through daily check-ins and by consistently monitoring gas flow, temperature indicators, and relief valves.

We know a bright flame is not something community members want to see. Refinery employees work hard to safely adjust and balance refinery operations around the clock to minimize the need for flaring and reduce visible impacts One way we do this is by injecting a mixture of steam and air on the flame, similar to how you would waft air onto a smoky campfire. Refinery operators have a constant live video stream of the flame with heat sensors so they can monitor and adjust the steam to continually have a smokeless flare.

We are proud of the results we have seen so far, but we are always working to better understand how we can adjust procedures and continue to improve.

For information about local air quality and real time data, please visit Clean Air Sarnia and Area (CASA).