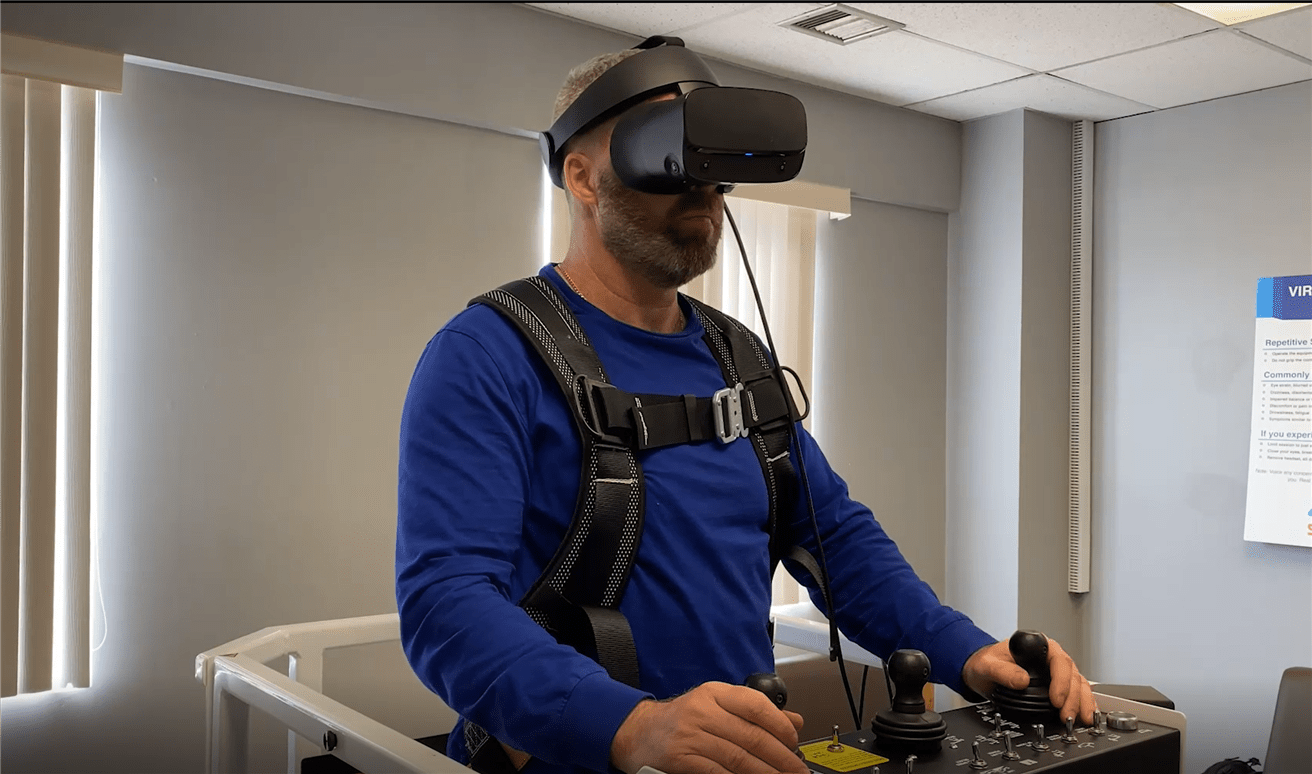

The thing is, you’re not on an actual aerial work platform at all. In fact, you are in an office, training on Suncor’s brand-new virtual reality (VR) AWP simulator. Aerial work platforms are vehicle-mounted units used to position a worker at an elevated worksite. The simulator is enhancing safety and improving training efficiency at Suncor’s Syncrude site.

“Traditional training involves six to seven hours of classroom training, followed by testing on a real aerial work platform before someone is certified to operate,” says Jeff Butler, a Training Advisor for the maintenance team at Syncrude. “Our simulator training is more comprehensive and sets our workers up for safe, successful operation in the field.”

Workers take online training to understand the basics of operating an aerial work platform, followed by several sessions using the simulator and finally operating a real one under the supervision of a certified mentor.

“This technology is an all-around win for training at our operations,” adds Jeff. “The sky is the limit for where VR technology can go. I think you could see VR used more widely across the organization in the future.”

AWP training isn’t the only training to benefit from technology innovation at Suncor. Augmented reality technology is enhancing the way Suncor’s employees learn how to work in the various maintenance shops at our Fort Hills site.

The program is quite simple—an experienced employee will perform a task while wearing an augmented reality headset. As the worker completes their task each work step is captured by the headset using hands-free, voice, gaze or gesture commands. After the task is completed, trainers review the footage and break it down into steps. New employees can then put the headset on and watch a step-by-step process on how to perform the task with a virtual overlay over the real-life item. The task can also be viewed without the headset on a mobile device. It’s like having an experienced mentor walking you through the process and allows the user to learn by doing. The technology adds to the information available and provides a better training experience for the worker.

“This tool continues to improve our training processes for workers on site, driving safety and consistency through on-demand digital mentorship,” says Scott Chuchmuch, a trainer in the maintenance department at Fort Hills. “It makes our training process more efficient and improves safety by allowing workers to be hands-on with the tools right away without risking injury.”

The Fort Hills team conducted a test using this technology for a bolted flange assembly. A flange is a collar used to bolt two pipes together. The team brought together six employees who had no experience working with the assembly. With only the written instructions provided, the employees completed the bolted flange assembly. After using the written instructions, the trainers instructed the employees to complete the same task with the augmented reality tutorial. The employees were able to complete the same process with most employees having an accuracy rate around 99 per cent. The augmented reality headset training saw an accuracy improvement over 70 per cent for a first-time user. From this simple test, it’s clear to see the promise of this emerging technology and the positive effect it could have for our training procedures.

It’s an exciting time for training and the potential for these technologies is endless. These two projects highlight how technology can be applied to improve training and safety at Suncor sites. It’s part of Suncor’s commitment to being an energy leader and constantly innovating to improve our operations.